|

|

|||||||||||||||||||||

|

SmartDO eNews Sep. 19, 2012

: Structural Optimization with SmartDO and its Direct Link to ANSYS

Workbench

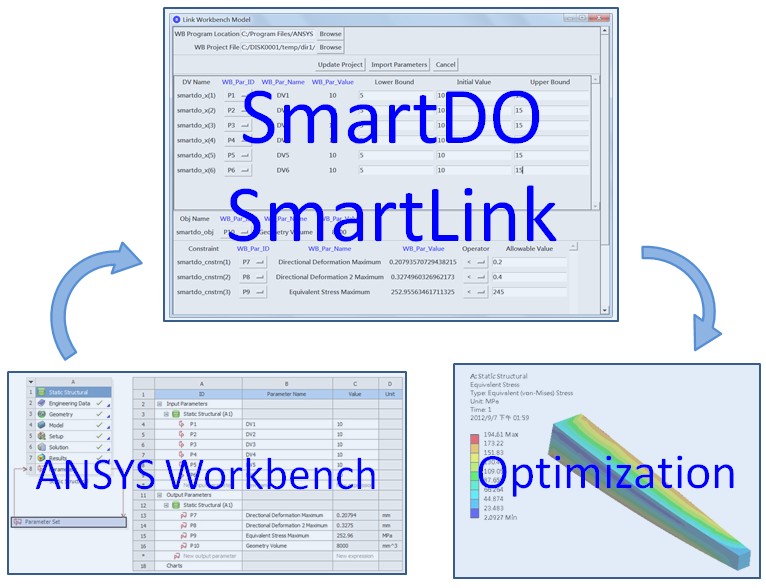

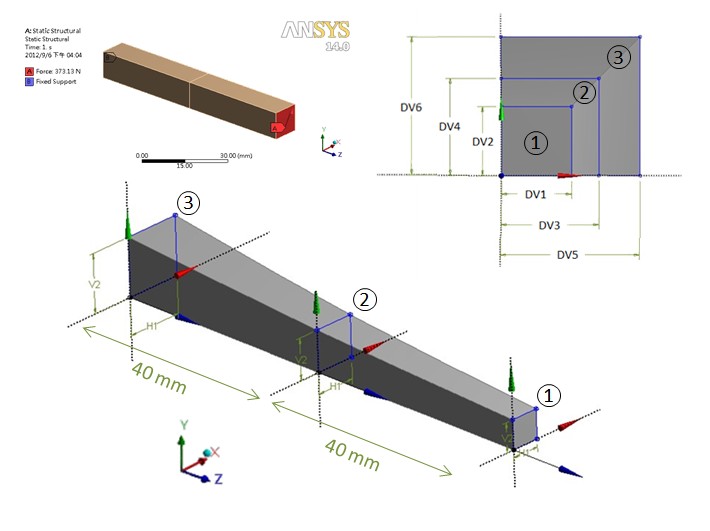

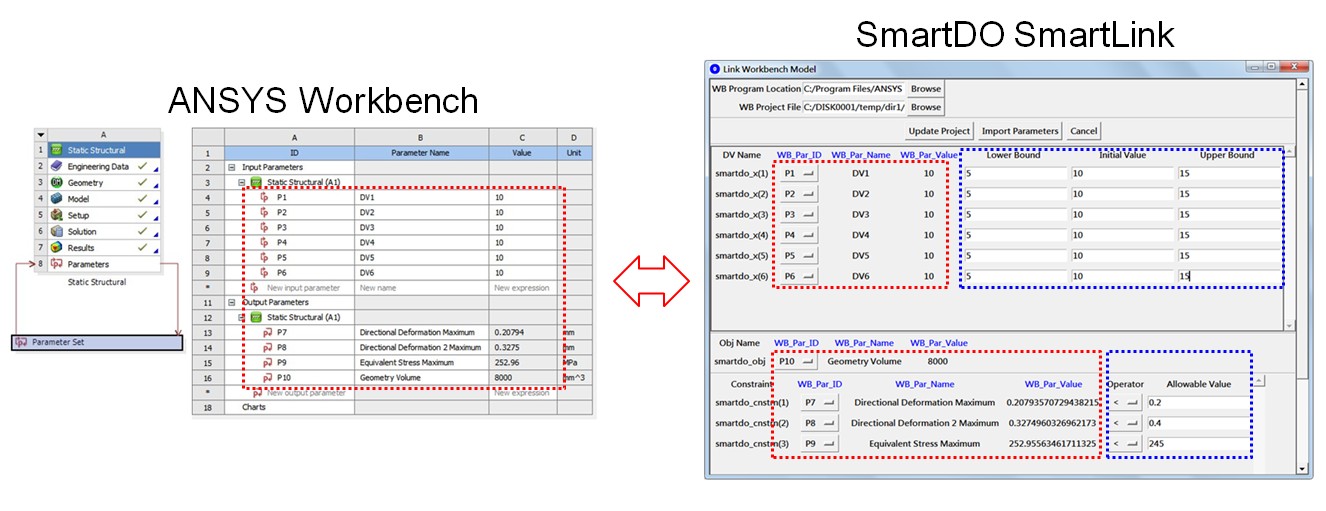

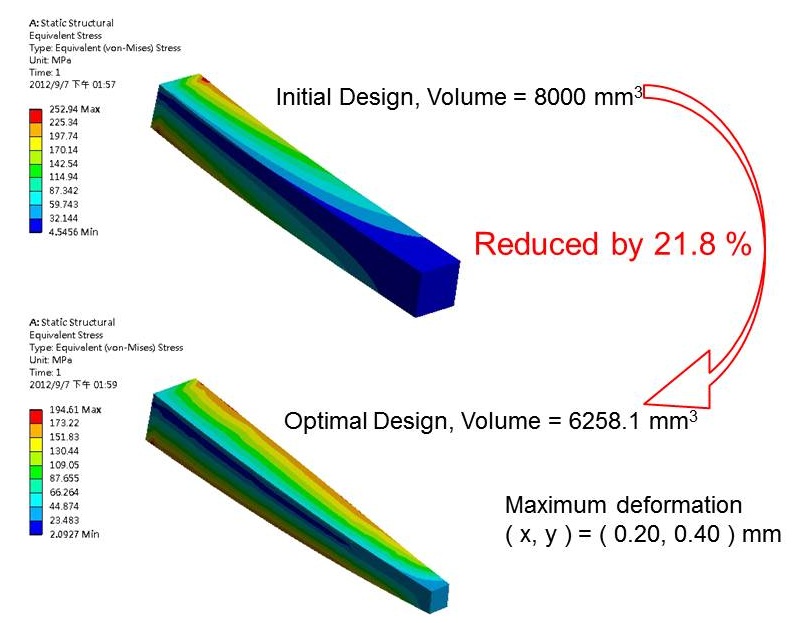

Introduction In this issue of SmartDO eNews, we will introduce the new SmartLink module of SmartDO. SmartLink can link with the parameters in ANSYS Workbench directly with easy-to-use GUI. With the powerful solver in SmartDO, the user can cross-link any parameters in Workbench to any design parameters in SmartDO, such as design variables, objective function, and constraints, and SmartDO will usually solve the problem smoothly without much difficulty. We will use a simple 3D cantilever beam to demonstrate this convenient and efficient new interface. Description of the Problem Consider a 3D cantilever beam with its design variables and boundary conditions shown at Figure 2. It is fixed at one end, and applied a force of FX=200N and FX=315N at the other end. The design requirement is to minimize the volume of the beam, with limitation on the maximum deformation at the X, Y directions, and the maximum equivalent stress. As stated before, the goal of the design optimization is to minimize the volume of the beam, subjected to limitation of maximum deformation and equivalent stress. The design optimization model is formulated as Find : DV1, DV2, DV3, DV4, DV5, DV6 To Minimize : Volume of the beam Subjected To: Maximum X deformation < 0.2 mm Maximum Y deformation < 0.4 mm Maximum equivalent stress < 245MPa As shown in Figure 3, on the left hand side is the parameters table in ANSYS Workbench. This table can be directly imported into SmartDO SmartLink with just one click of button, as shown in the right hand side of Figure 3. With the pull-down menu in SmartDO, the user can select any parameters in Workbench, and assigned into objective function, constraints or design variables in SmartDO. The user then specifies some necessary values from the formulation mentioned above (constraints, lower/upper bound and initial values of design variables, etc.). Then with few clicks of buttons, SmartDO will begin the optimization process. Final Results and Hardware Verification With the powerful and robust solver in SmartDO, the user can usually just use the default solver without any tweaking. With the combination of SmartDO and Workbench, the following result is obtained after design optimization.

Figure 4

Direct Linking Between SmartDO/SmartLink and ANSYS Workbench

In this issue of the SmartDO eNews, we show you how the SmartLink interface in SmartDO can easily link with the parameters in ANSYS Workbench. With the powerful and stable solver in SmartDO, design optimization can be easily performed. For details about SmartDO, please visit our web site at http://www.SmatDO.co All brand or product names are trademarks or registered trademarks of their respective holders. Copyright of all materials in the links belongs to their respective authors. I am not responsible for any contents inside any links. (c)Copyright, 2005-, FEA-Opt Technology. All rights reserved.

|

|

|||||||||||||||||||||

| Copyright © FEA-Opt Technology Design by Iron Spider | ||||||||||||||||||||||

|

|

||||||||||||||||||||||