Fan and Turbine Blade Design Optimization

|

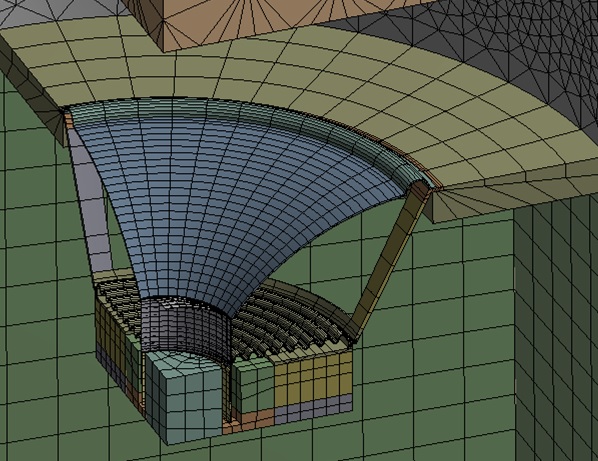

Since 2004, SmartDO has been applied to the multi-physics optimization design of many fan and turbine blades. Over the years, we have accumulated many experiences and customer examples to assist customers in multi-physics optimization design for various fan blades In the last link of this paragraph, we will introduce one of the successful cases, using SmartDO to integrate ANSYS to develop a customized fluid-structure interaction optimization design system for turbine blades. Through the integration between SmartDO and ANSYS Workbench, SmartDO increased the flow rate of the original blade design by 14%, while reducing the maximum stress value of the blade under the action of fluid and mechanical operation. For details, please refer to this SmartDO Newsletter。 |

Semi Conductor : Packaging, Material Fitting and Optimization

Nozzles & Ejectors Aerodynamics Performance Optimization

Automotive Industries Design Optimization

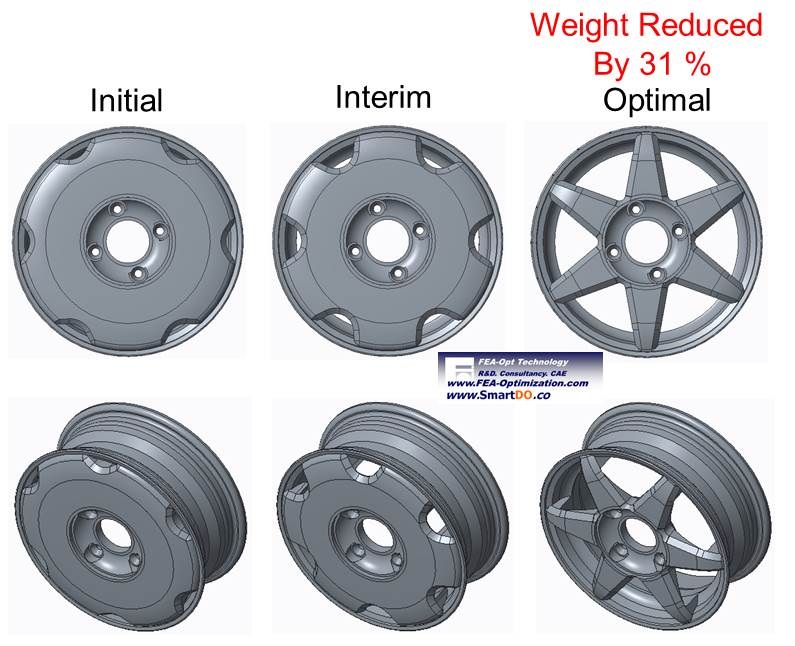

Light Weight Structure

Heating & Cooling Performance Optimization

Machine Tools Design Optimization

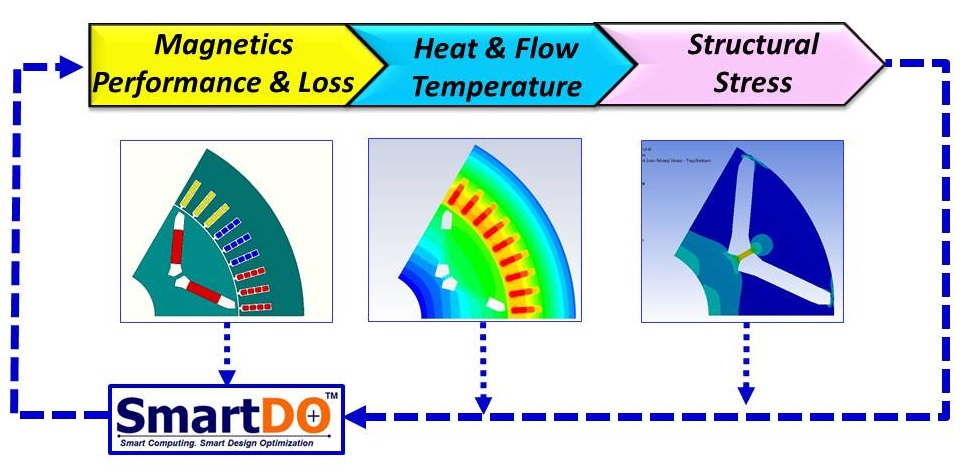

Electric Motor : Torque, Ripple, Cogginh, Efficiency and Multiphysics Optimization)

Speaker Acoustic Performance Optimization

Digital Production Line Integration & Automation

Other Successful Application

|

Successful Stories at Our SmartDO Newsletter Physics and Disciplines

Specific Application

|