Using SmartDO to Improve 70% Performance for Semiconductor Equipment Exhaust Plate (for Wafer) Through Automatic Design Optimization

25-DEC-2025

Using SmartDO to Improve 70% Performance for Semiconductor Equipment Exhaust Plate (for Wafer) Through Automatic Design Optimization

In advanced semiconductor manufacturing, flow-field uniformity is process quality. Even small non-uniformities in exhaust flow above the wafer can lead to particle contamination, etching non-uniformity, and yield loss. This case demonstrates how SmartDO, an AI-powered automatic design optimization platform, delivers a quantified, production-ready 70% improvement for a real semiconductor exhaust plate design through tightly coupled CAD-CFD optimization.

Why Optimizing the Semiconductor Equipment Exhaust Plate

The exhaust plate directly governs gas removal uniformity above the wafer surface. In the original design, the velocity distribution at the R120 inspection line showed a standard deviation / mean of 0.1488, indicating significant non-uniformity. At the same time, total exhaust performance must be preserved, with outlet mass flow rate constrained to remain above 90% of the original value ( > 0.0004815 ). This creates a classic conflicting, multiphysics design problem-ideal for SmartDO's global optimization engine.

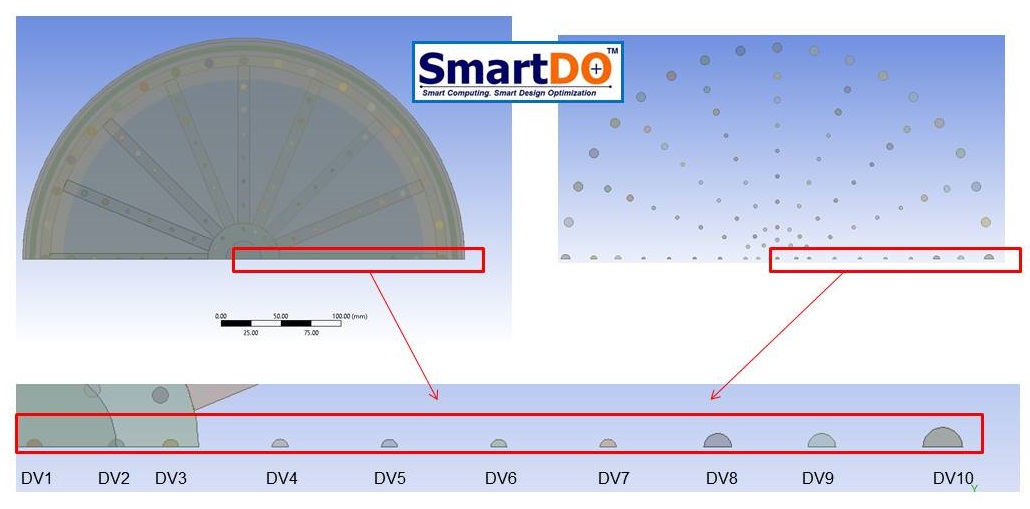

Figure 1 shows the overall configuration of the exhaust plate.

Figure 1 The Overall Configuration Of The Exhaust Plate

Parametric CAD of the Semiconductor Equipment Exhaust Plate

A fully parametric CAD model was constructed, where 10 exhaust hole diameters (DV1-DV10) serve as design variables.

- Each diameter was bounded by strict manufacturing limits (LB-UB), with different upper bounds for inner and outer regions.

- Angular hole patterns automatically followed diameter changes, ensuring geometric consistency without manual remodeling.

This setup enables direct geometry-driven optimization, eliminating trial-and-error CAD iterations while keeping the model fabrication-ready at every step.

Also, with the unique S.A.F.E.D (Secured Adaptive Function for Error Detecting) feature in SmartDO, it can learn from computational history, and automatically detect/avoid modeling failure of CAD.

Figures 2 shows the definition of the 10 design variables.

Figure 2 The Definition Of The 10 Design Variables.

SmartDO Optimization Formulation

SmartDO formulated the problem as a global, constraint-driven CFD optimization tightly integrated with ANSYS DesignModeler and Fluent:

- Minimize velocity non-uniformity : OBJ= Standard Deviation / Mean of Velocity at @R120 line

- Outlet mass flow rate > 0.9 × original

- Velocity non-uniformity lower than the original design

- Observation plane: 1 mm above wafer surface

Using SmartDO's AI-powered global optimization strategy, the system automatically explored the design space and converged without local-minimum trapping. The entire optimization required only 127 full CFD simulations, highlighting SmartDO's cutting-edge computing efficiency.

SmartDO Optimization Result

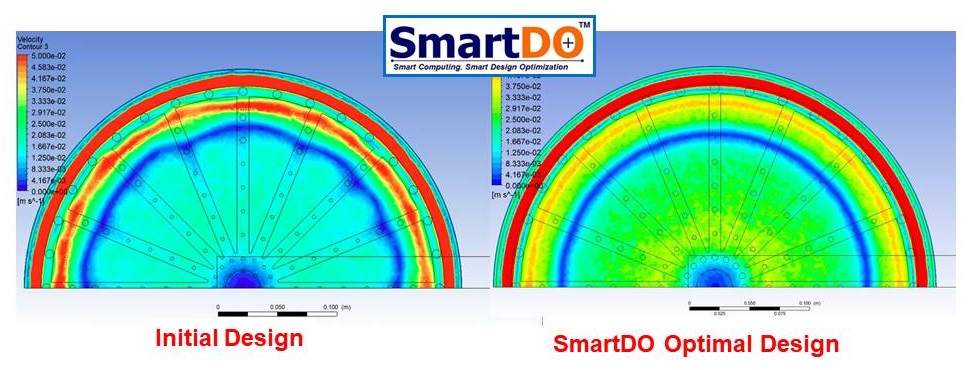

The optimized exhaust plate achieved a clear, quantified breakthrough:

- Velocity uniformity (Std. Dev./Mean @R120)

- Initial: 0.1488

- Optimized: 0.04459

- Improvement: +70%

- Outlet mass flow rate:

- Initial: 0.000535

- Optimized: 0.00057

- All constraints fully satisfied

This result demonstrates that SmartDO not only dramatically improves flow uniformity, but does so without sacrificing exhaust performance-a critical requirement for semiconductor equipment design. The optimized geometry is immediately manufacturable and validated by full CFD simulation across multiple inspection regions.

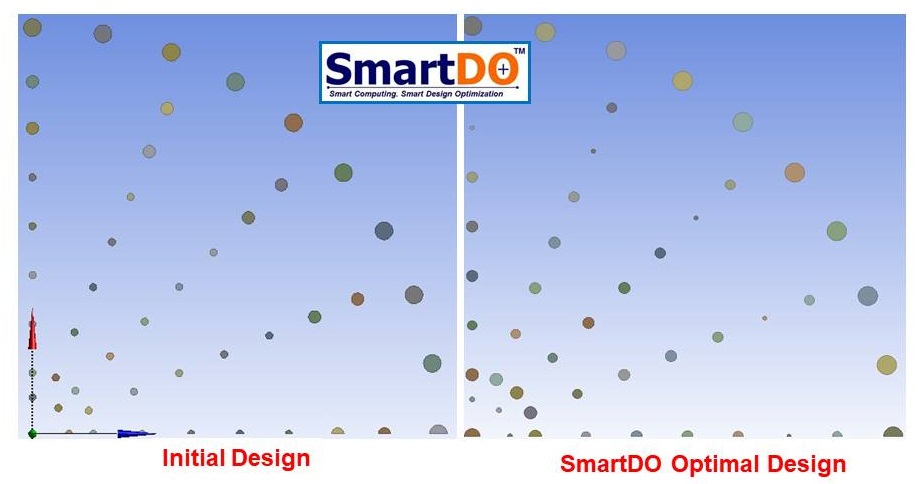

Figure 3 shows the initial (left) and the SmartDO optimal design (right) exhaust hole diameters of the plate.

Figure 4 shows the initial (left) and the SmartDO optimal design (right) velocity magnitude distribution of the flow field

Figure 3 The Initial (Left) And The SmartDO Optimal Design (Right) Exhaust Hole Diameters Of The Plate.

Figure 4 The Initial (Left) And The SmartDO Optimal Design (Right) Velocity Magnitude Distribution Of The Flow Field.

SmartDO Advantage

This case exemplifies why SmartDO stands out as a general-purpose, AI-powered, multidisciplinary/multiphysics automatic design optimization platform:

- Global optimization, not local tuning.

- Cutting-edge computational efficiency with minimal simulation count.

- Direct CAD-CAE coupling for real engineering hardware.

- S.A.F.E.D technology for automatically detecting/avoiding modeling failure.

- Quantified, defensible improvements ready for production.

SmartDO turns complex semiconductor equipment optimization into a systematic, automated, and high-confidence engineering process-unlocking performance levels unreachable by manual or traditional DOE approaches.

Advantages of SmartDO AI-Power + Multidisciplinary/Multiphysics Automatic Design Optimization

With Cutting-Edge Computing Efficiency, SmartDO provides engineers with a seamless Push-Button Automatic Design Optimization Solution and a Digital Production Integration and Automation Platform with the following unique features

- One-page GUI configuration

- One-click automatic optimization design

- Proved in optimization problems with more than 240 design variables

- Multidisciplinary/Multiphysics automatic design optimization

For more information about SmartDO, please contact us.

More Information

FEA-Opt Technology Co. Ltd. is an international RD/Consultancy/CAE and Software firm. We provide superior RD/consultancy services to our customers, and customized solutions for each customer's special need.

SmartDO, our flagship product for Smart Design Solutions, is A General-Purpose AI-Powered CAE Optimization Platform. It provide unique technology for push-button automatic design optimization and Digital Production Line Integration and Automation. For details about SmartDO, please visit our web site at http://www.SmartDO.co/